Metal surfaces need adequate protection – that's a common fact for decades.

Many different anti-corrosion products and galvanical processes on the market claim "to have a leading" protection position. However the user is pretty much left alone with a confusing number of possible materials and even more so when it comes to their correct application.

Having a closer look at the real technical requirements things become a little bit easier. Most requisitions cover a static anti-corrosion demand which paints or galvanic treatments can easily handle. On the other hand a remaining part requires dynamic protection qualities! In addition to the basic anti-corrosion demand, mechanical forces exist overexceeding common solutions. Impact, wear or immersion conditions require simply more. That's where synthetic elastomeric coatings jump in with its enhanced heavy-duty corrosion protection properties.

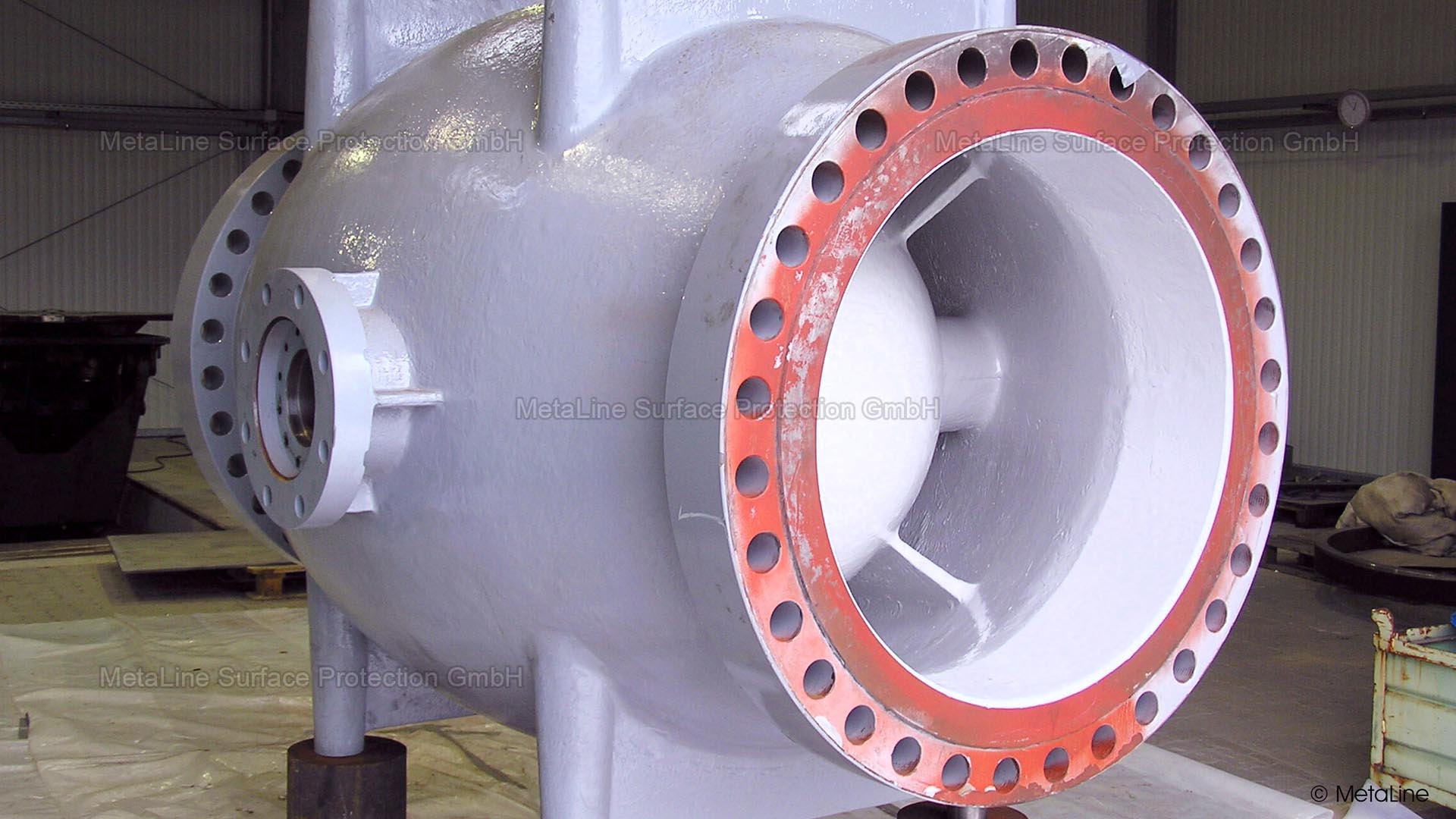

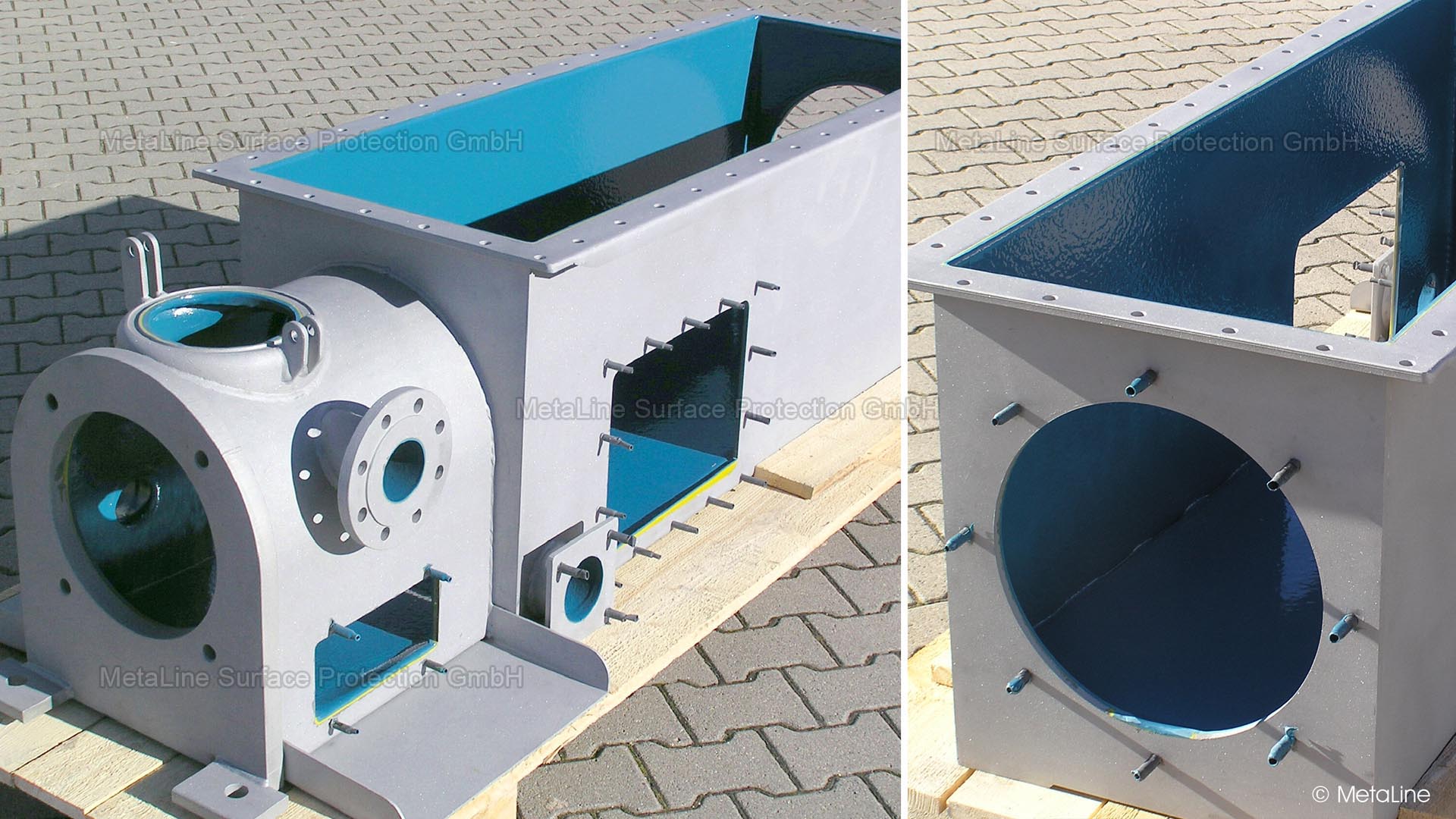

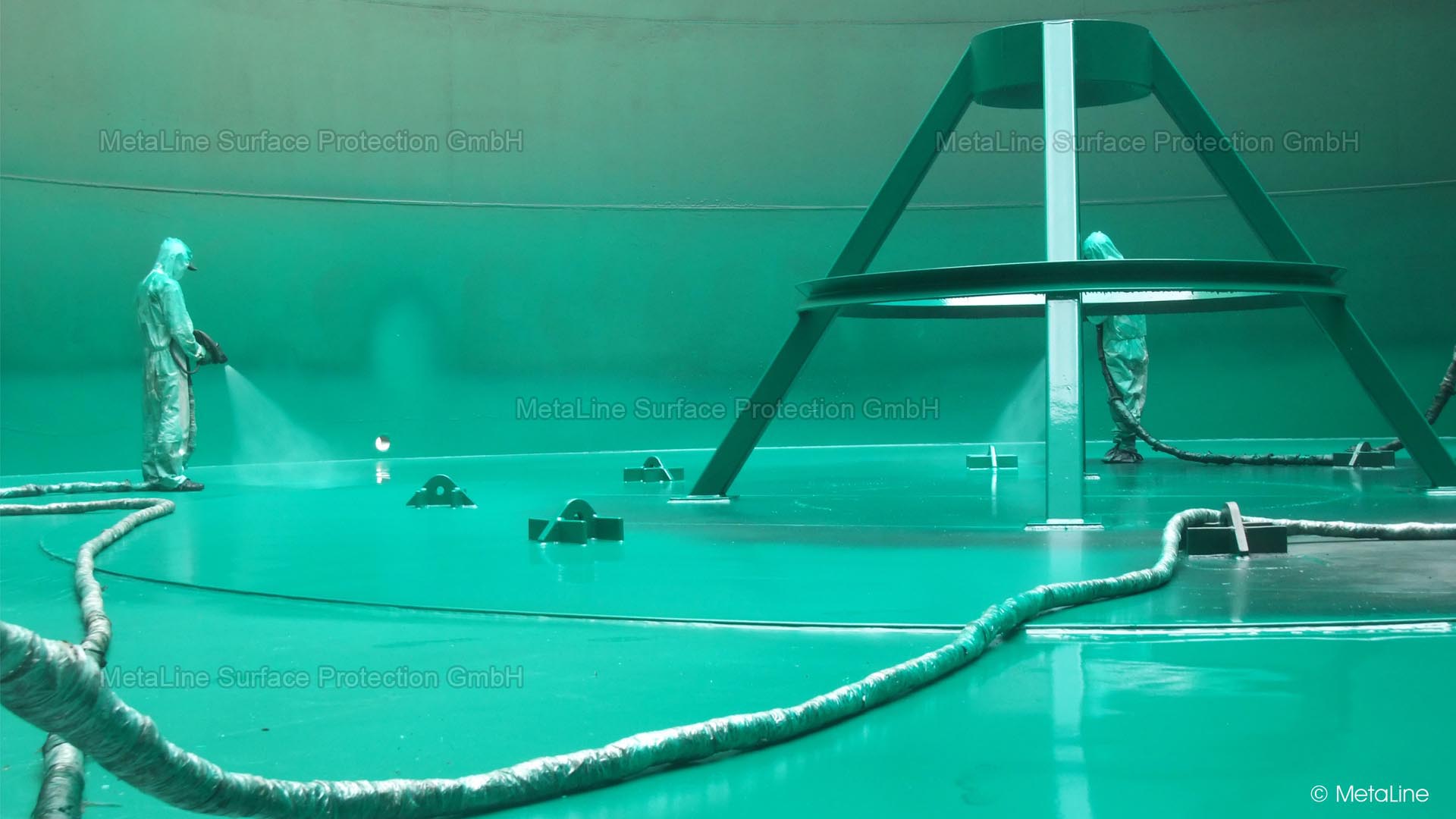

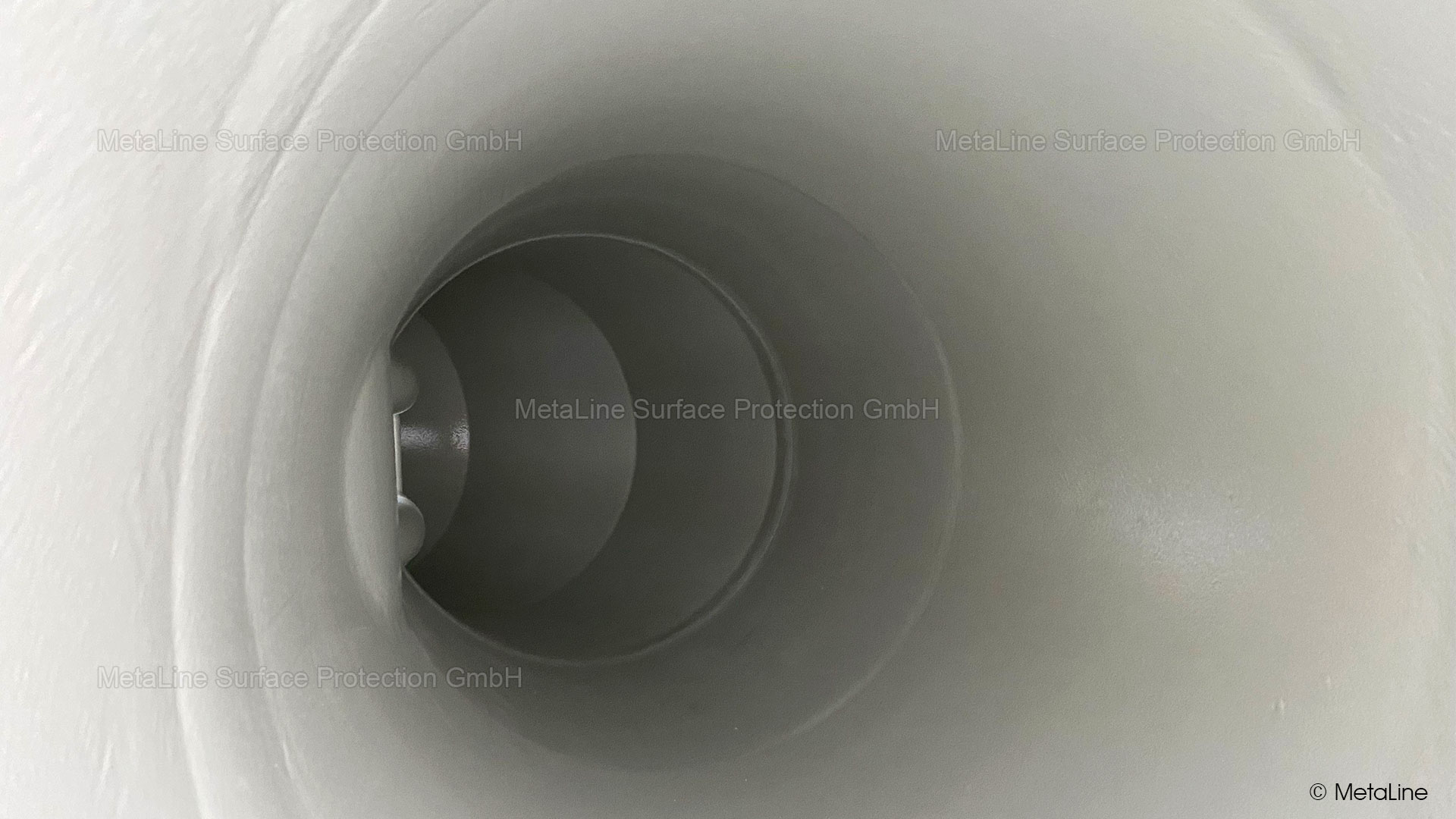

Corrosion protection - for the most difficult cases Objectives MetaLine surface protection systems help to solve this important processing problem. When it comes to corrosion protection, their strategy is two-fold. Primarily, MetaLine 924 which may be applied with a brush is used as an electro-chemical active (anodic) pretreatment measure offering a galvanizing protective function. Even with partial damages, the self-healing characteristics – similar to hot-dip galvanizing – protect against corrosion attack and borderline penetration. Then follows spray-on seamless encapsulation with a high-performance elastomer belonging to the MetaLine Series 700. This permanent barrier offers protection against direct medium contact, exposure to weather, humidity, impact, mechanical disturbances or permanent immersion conditions. Technical solutions in detail MetaLine Series 700 - Elastic duplex corrosion protection for severe (off-shore) requirements.

MetaLine Series 700 protection systems make the correct material selection saver. When it comes to corrosion protection, the strategy is a duplex one. Basic treatment with MetaLine 924. It is used as an electro-chemical active (anodic) pretreatment. Offering additional adhesion on special alloys as well as a galvanizing protective function. In case of damages, the self-healing characteristics – similar to hot-dip galvanizing – protect against corrosive attack. Final treatment with a sprayed-on, seamless encapsulation by a high-performance elastomeric skin. This barrier offers full resistance against exposure to weather, humidity, impact or mechanical disturbances. MetaLine Series 700 – Highly-elastic duplex corrosion protection Sprayable coating system for heavily dynamically stressed off-shore requirements. Shock absorbing, vibration resistant, solvent-free. Suitable up to 60 °C (140 °F) under immersion condition. MetaLine Series 100 XTM – Rest-elastic mono corrosion protection By brush, roller, airless- or cartridge-spray self-applicable coating system. Exceptionally chemical resistant. Solvent-free. Suitable for permanent immersion conditions of up to 130 °C (270 °F).