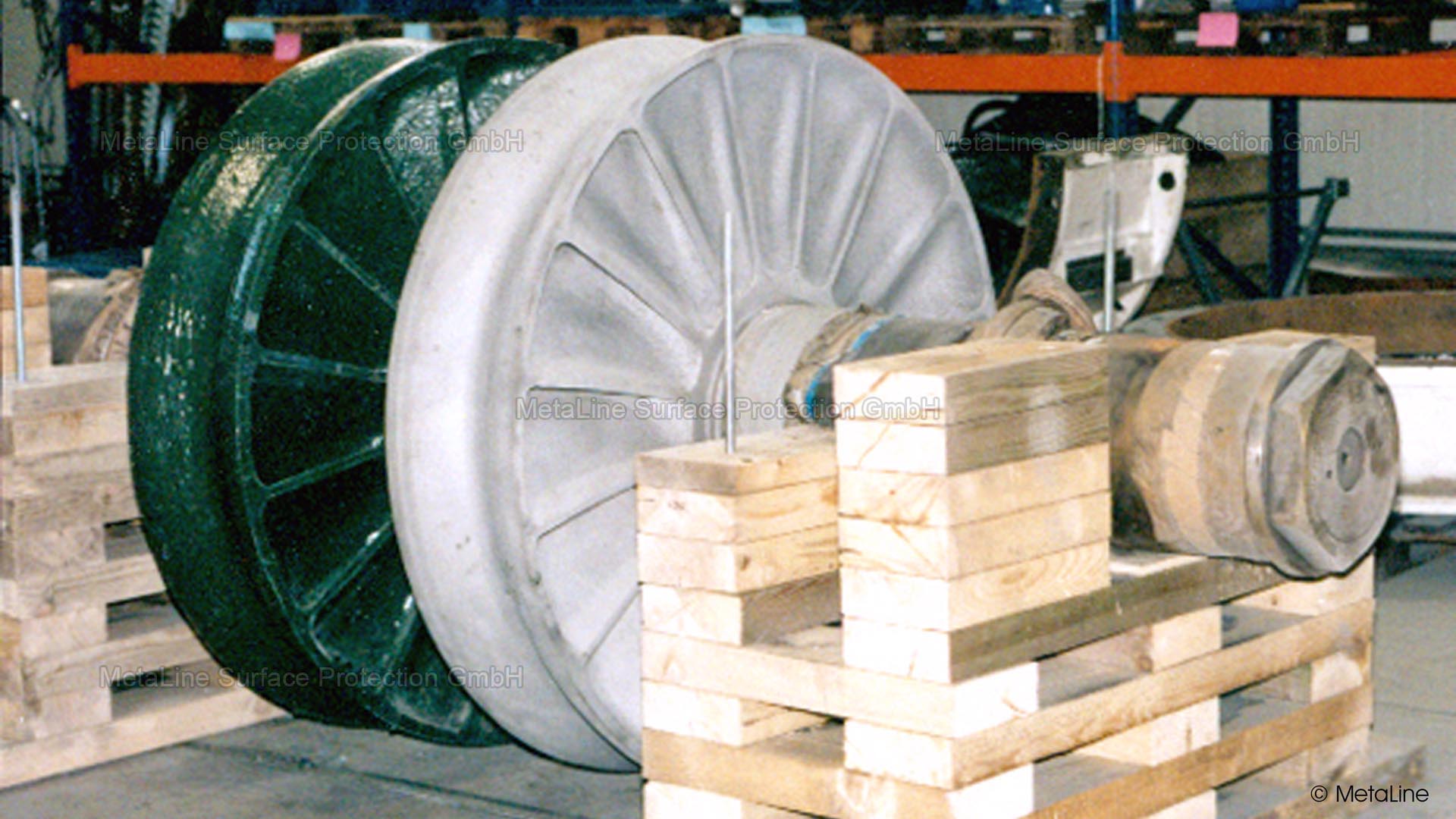

The conveying process of liquid or semi-liquid media represents a continuous wear process. The hydraulic efficiency and the static stability of the impeller become of concern owing to a certain degree of wear. If it breaks, major consequential damage is almost inevitable. Partial repairs carried out early enough preserve the remaining substance and prevent a larger damage.

Ask us about: rotors, vane profiles, vacuum rotors, rotary pump impeller, open / closed impellers, single-channel / multi-channel impellers, mixers

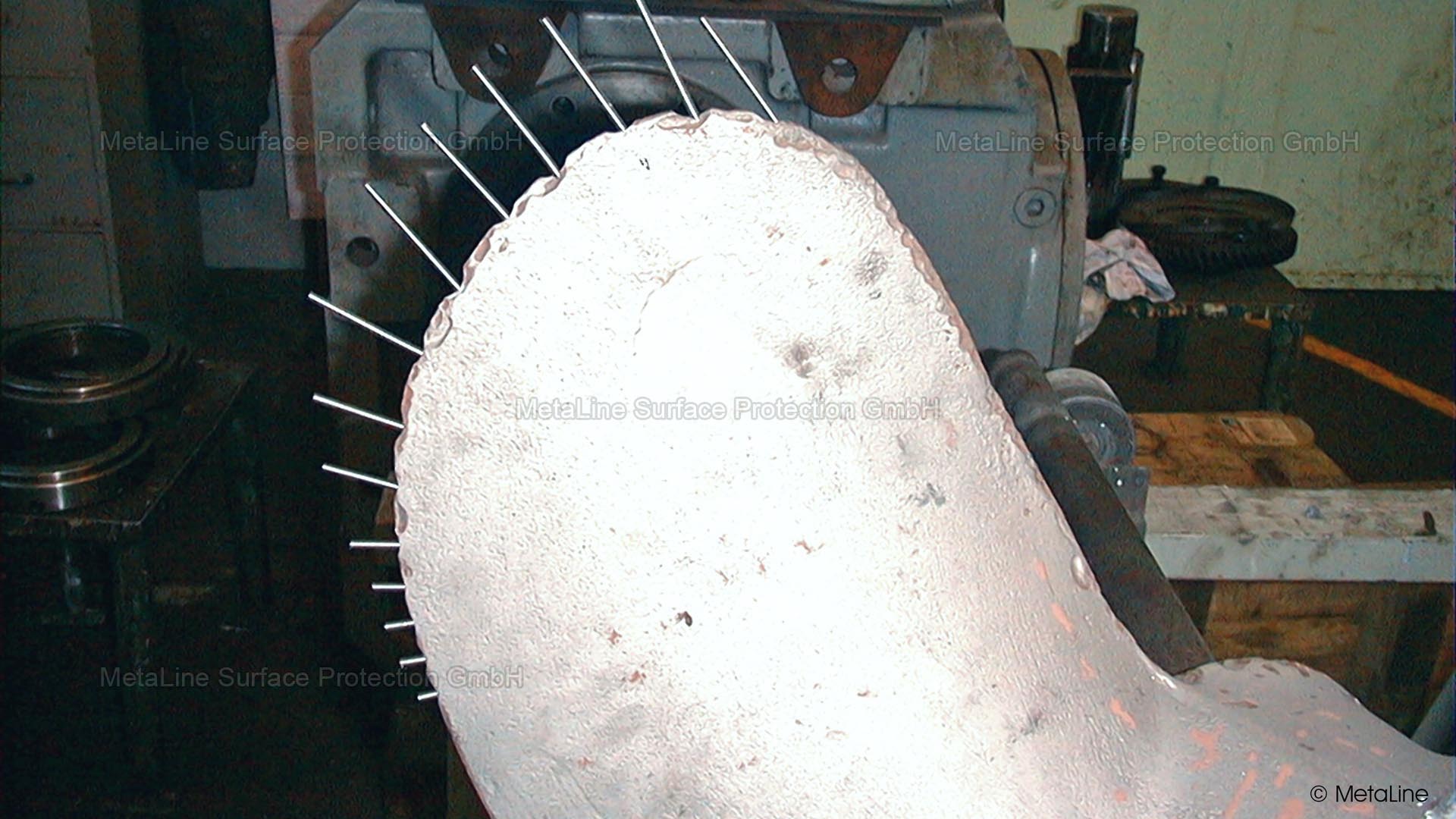

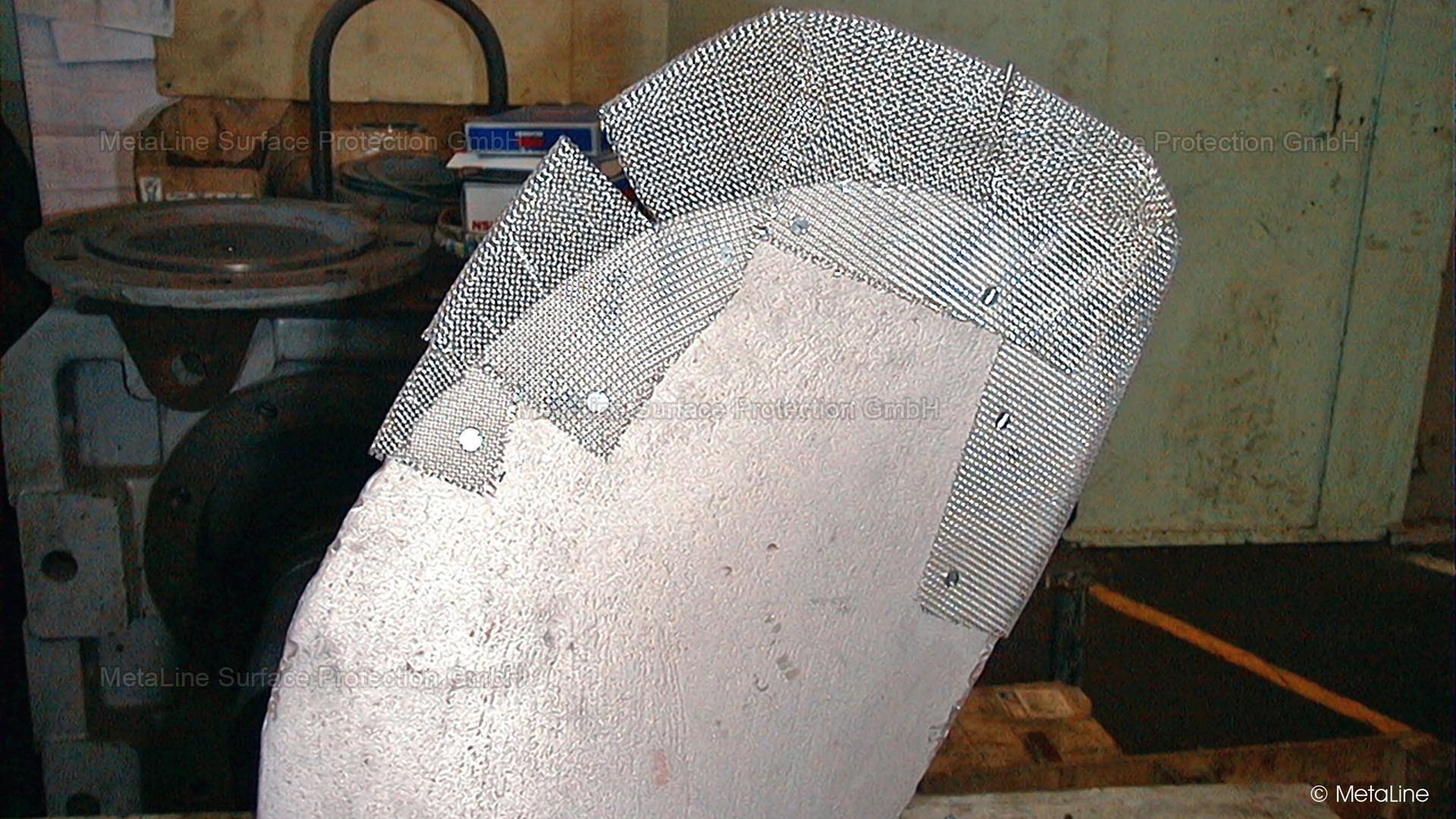

KSB Pumps Test MetaLine Series 700 – Sprayable / OEM Manufacturer quality MetaLine Series 700 coatings absorb destructive impact energy through permanently elastic material properties. Layer thickness is adapted individually to the stress parameters and flow conditions of the pump design. This usually results in 4–5 times higher lifetimes for impellers coated with MetaLine compared to unprotected cast iron designs. MetaLine Series XL – Trowel- or brushable / Repair quality MetaLine XL series are polymeric repair materials for restoring worn structures and geometries. Used in good time, they prevent further degradation of the impeller and static stability losses. The materials are characterized by an extraordinary strong substrate adhesion as well as their good corrosion resistance.